SEAS Thor

Part 2

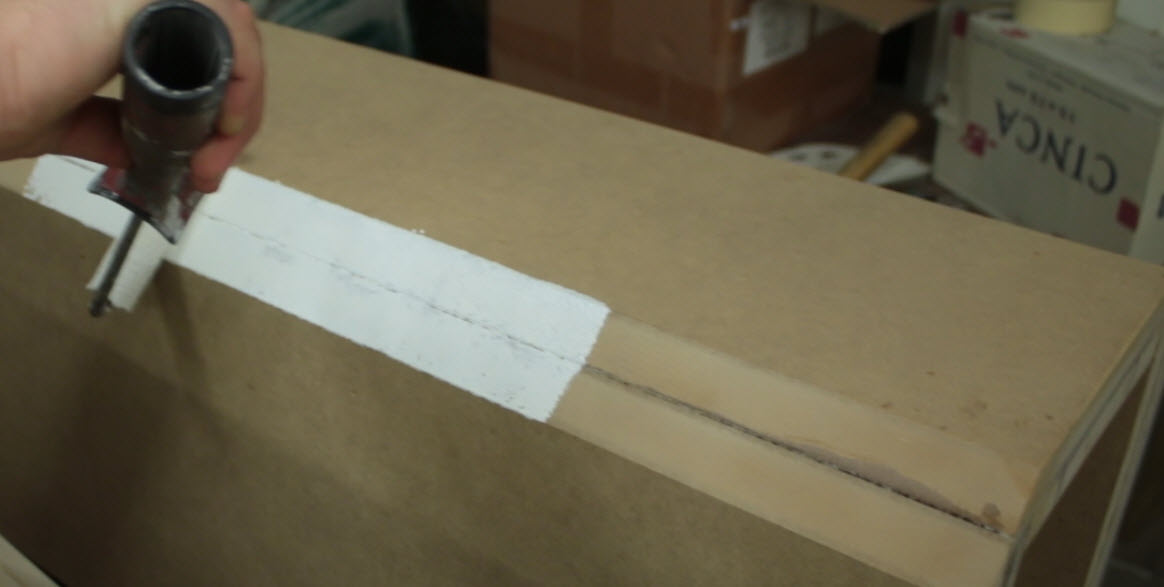

Sanding and priming and filler

The process takes a lot of time.

Sanding, priming, filling, over and over againg for a week or two.

Filler has a tendency to shrinkresulting in visible lines.

I do not have access to a tablesaw big enough to chamfer the cabinets, so this was the only option.

Final priming

Making a speaker stand

the bottom piece fits snuggly, the stand will be made from some old speker stand with three spiken.

The black matte powdercoat looks fine, forgot to take proper pictures..

Some drilling and cutting to do

Some welding and a testfit, later spraypainted black

Black coat

Painted over and over again with thin layers, perhaps at later stage final coat and polishing...

Components and filter installation on next page