F31 front brakes replaced

2017 F31 320dA -New front brakes

Service indicator suggested that front brakes were due for a check.

Car is currently at 84000km or

53000 miles.

.

I attempted a reset of the service message by using the odometer process, it did not allow it.

One very reliable reason to why not, is that the wear indictor is in open circuit state -i.e. it needs to be replaced along with the pads.

Tools needed

17mm six point for wheel bolts

Jackstands

Floor jack

Torque wrench 1/2"

Proper square handle 1/2"

Various allen keys

Brake bleeder

Various open end wrenches

Scotch brite

Metal files

Wire brush

Chisel

Hammer

WD-40

Brake cleaner

Caliper piston compressing tool

or big soft jaw pliers.

Parts list:

25199.195.1 Brakepads

150.2900.20 Rotor x2

8DZ 355 205 retainers and glidepin rubbers

24.8190-0006.2 Wear indicator

In the garage -preparations

Before starting the brakeparts dissasembly, preload the master cylinder, and (optional)use suitable tool to extract brake fluid from the reservoir,

Loosen wheel bolts.

Lift and secure the car on jackstands.

Remove the wheel to access the brakeparts.

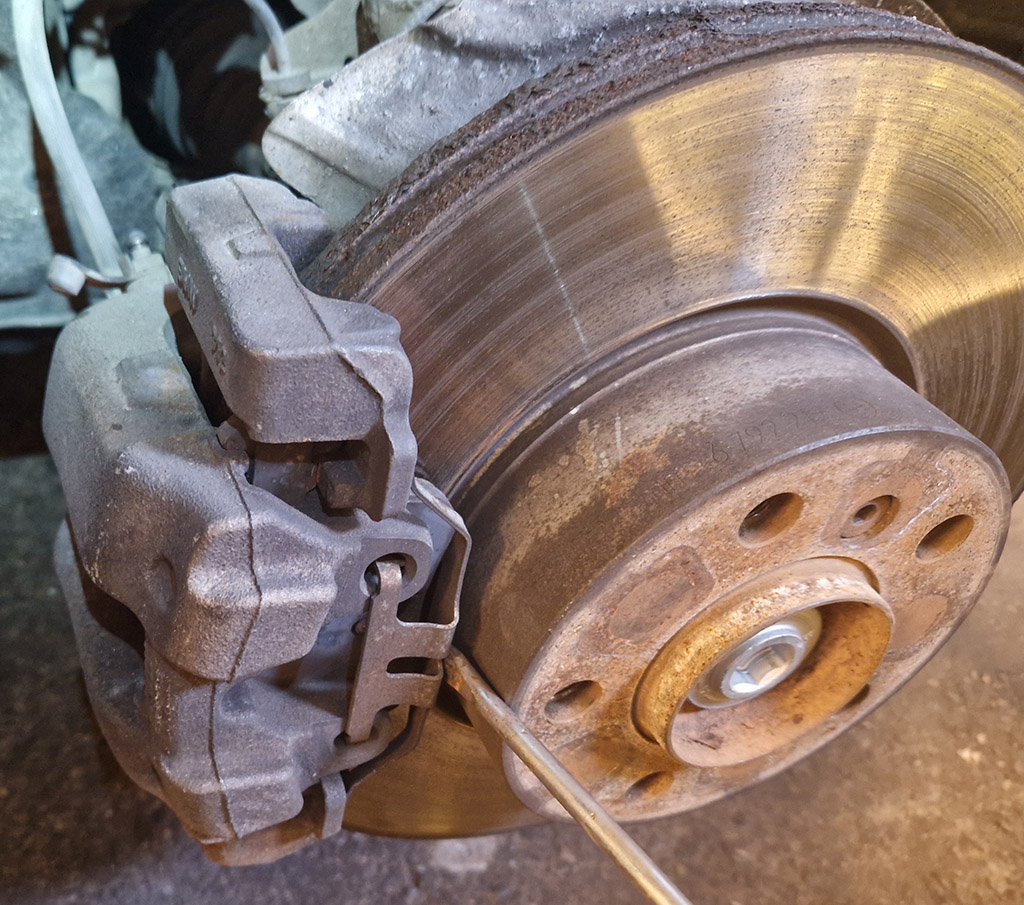

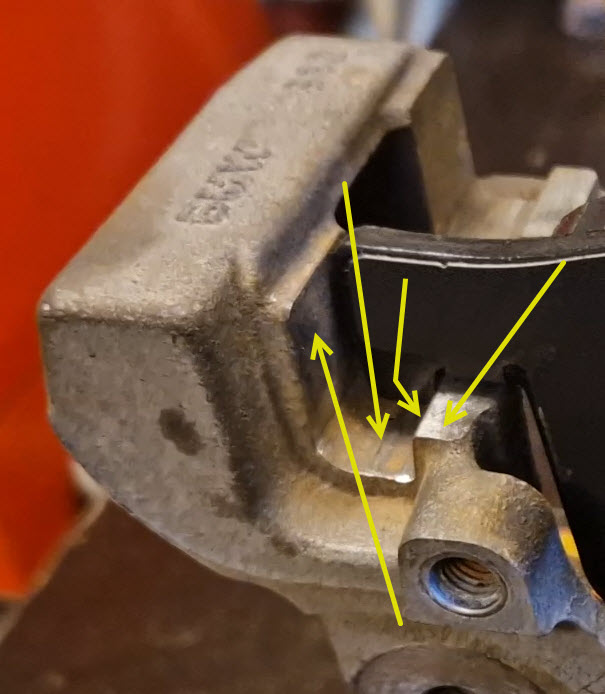

Inspection port in caliper shows indicator has been touching the rotor:

Open circuit wear indicator = no reset possible.

In the garage -teardown

Open cable connection box.

Carefully, do not damage the brittle hooks.

Unhook rubber, some WD-40, can help.

The slidepins need some cleaning.

I used the allen socket and a powertool to spin them in scotchbrite.

Old brake pads, inspection

Wear is even and there is no noticeable rustjacking. it pays keeping salt away by washing the car regularly.

Retract the caliper piston

Where possible, I try to avoid pushing old brakefluid back inte the system.

By using the preload on the brakes and the reservoir emptied the cliper can be pushed in without risk of overflowing.

Old brake fluid will be forced out the bleeder instead.

Connect hose, bleed the brakes

by pushing the caliper piston in.

When done, with hook, hang the caliper on the spring, dont let it hang by the brakehose.

Remove the rotor

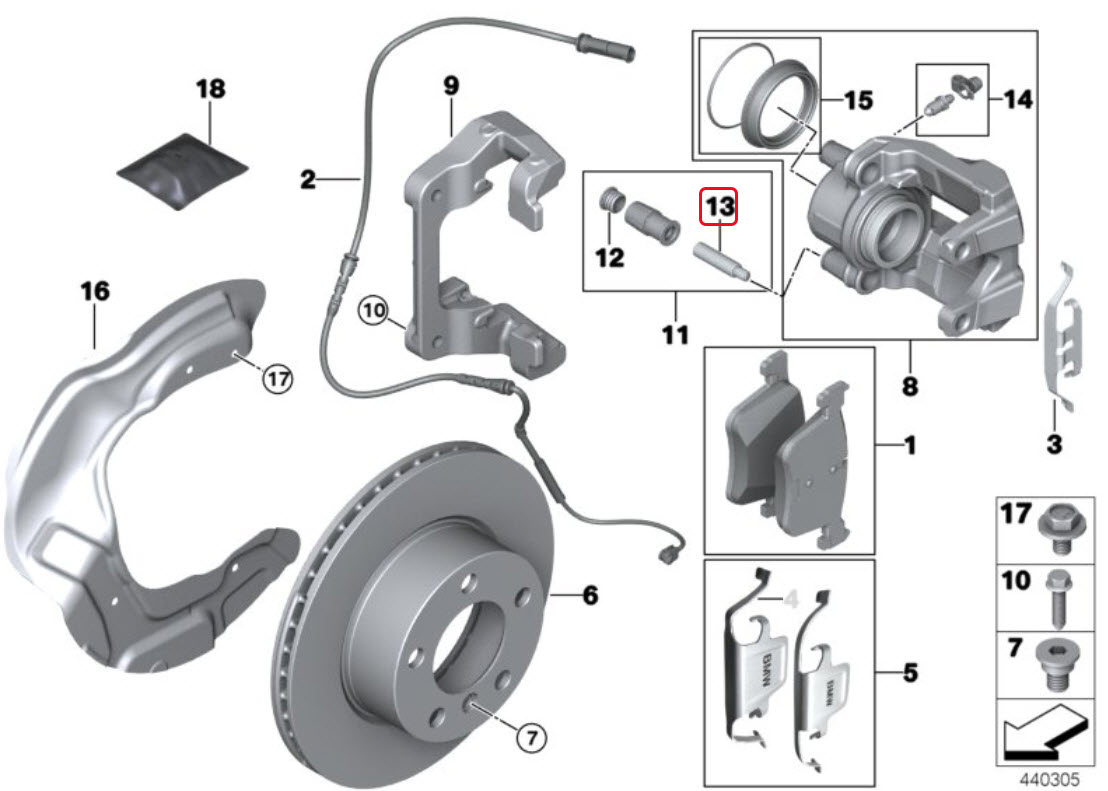

Remove the caliper braket, no 9 in picture.

I was lucky, the car is not very rusty and the caliper bracket bolts came out without issue

The retaining screw can be removed with hammer and handle or impact screwdriver.

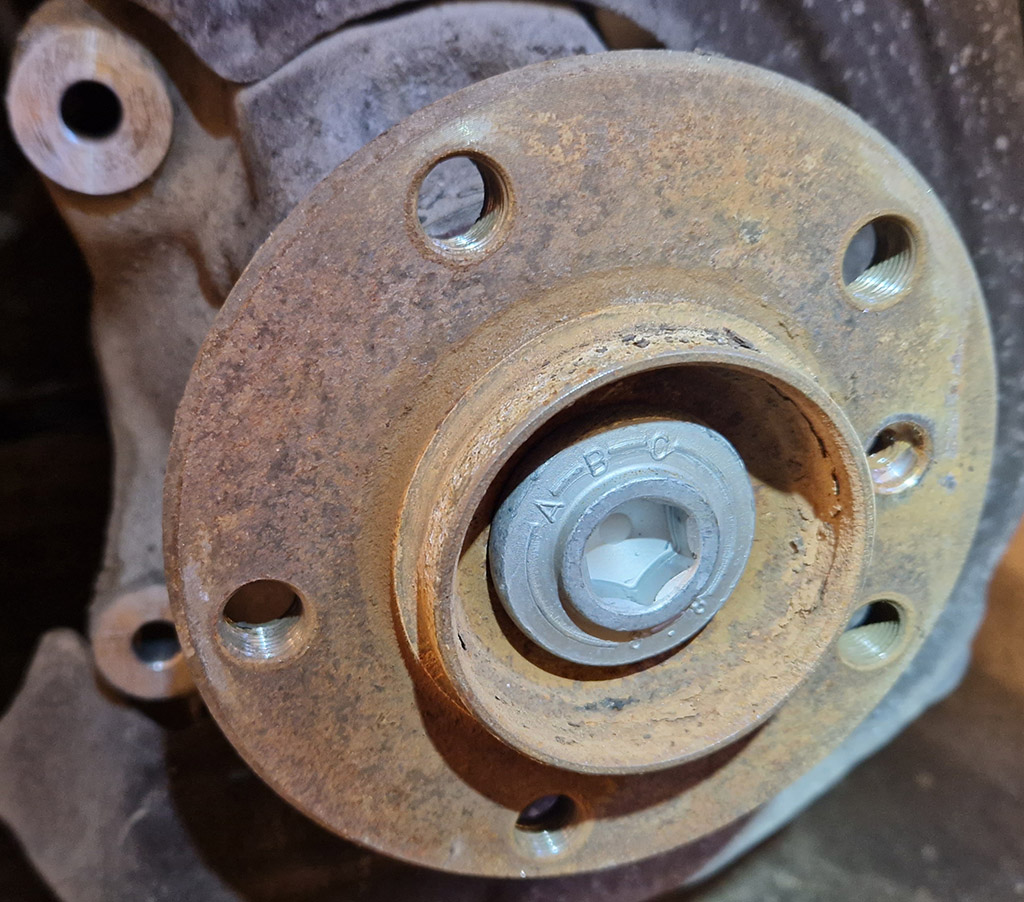

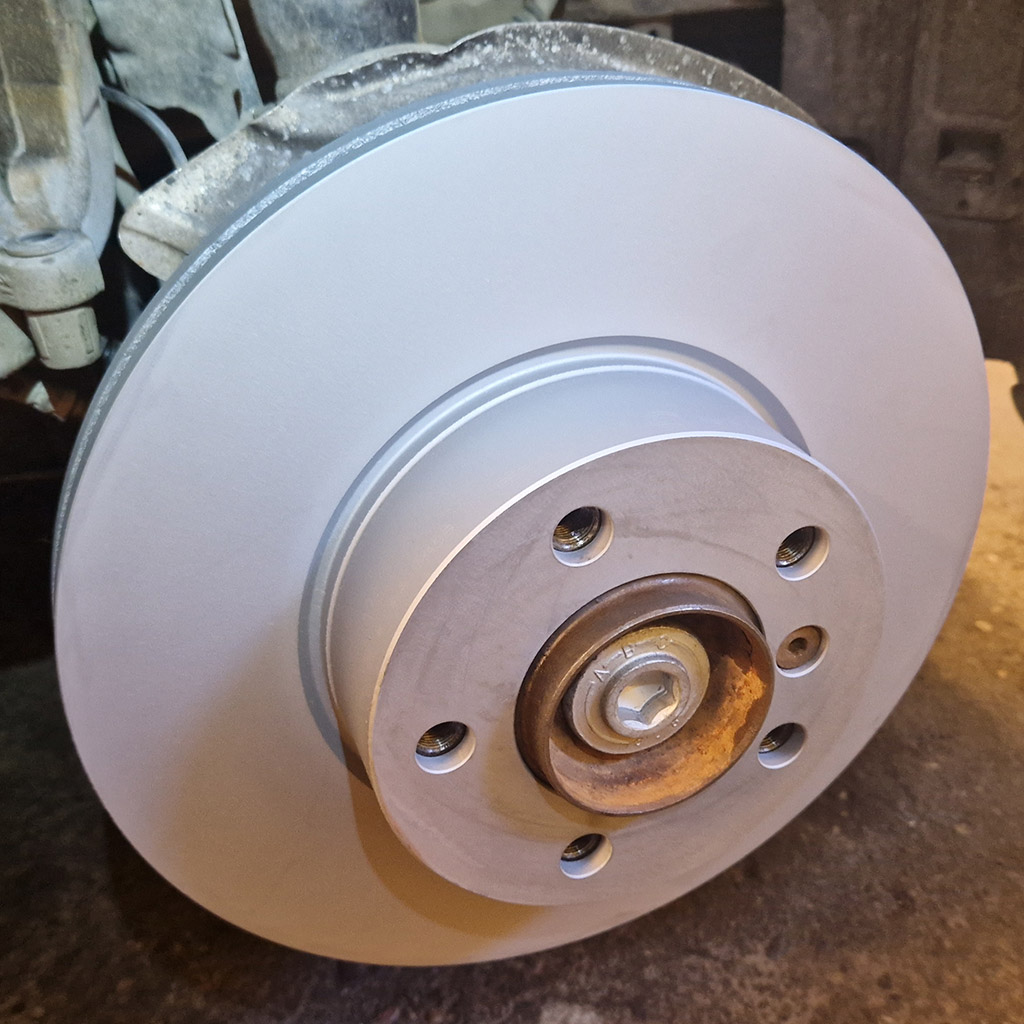

Cleaning wheel hub

Rust will and is pushing the disc unevenly, cleaning and adding thin fluid film is important in these salty environments.

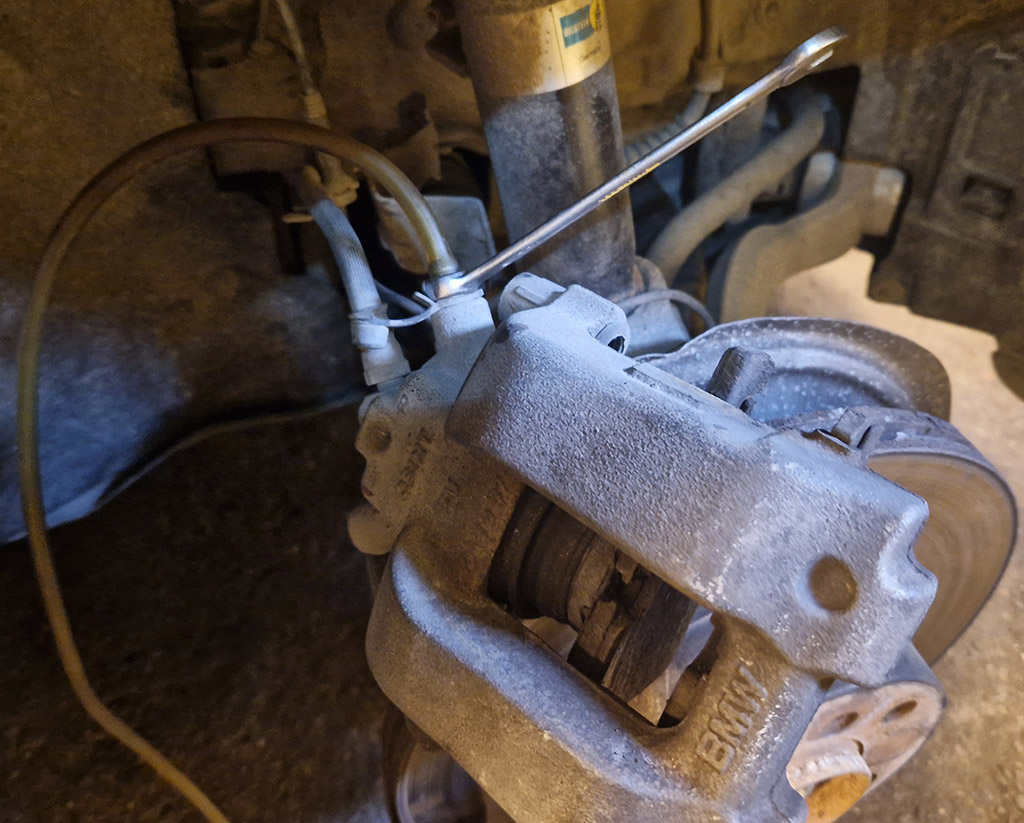

Installing new rotor

It does not matter if the new rotor is coated or not, brake cleaner is

good practice.

New Zn coated rotors, no visible dents.

Good fitment, no unevenness. screw reinstalled

Preparing the caliper

Slide pin bushings holes will swell shut with rust.

This has the consequence that the slide pin will be clamped

and thus has harder time moving.

Using a dremel tool, holes will be cleaned and fluid film added before installing new bushings.

Before inserting the glide pins, thin coat of something

in a small pack

is added.

Glide pin, easily moves inside bushing.

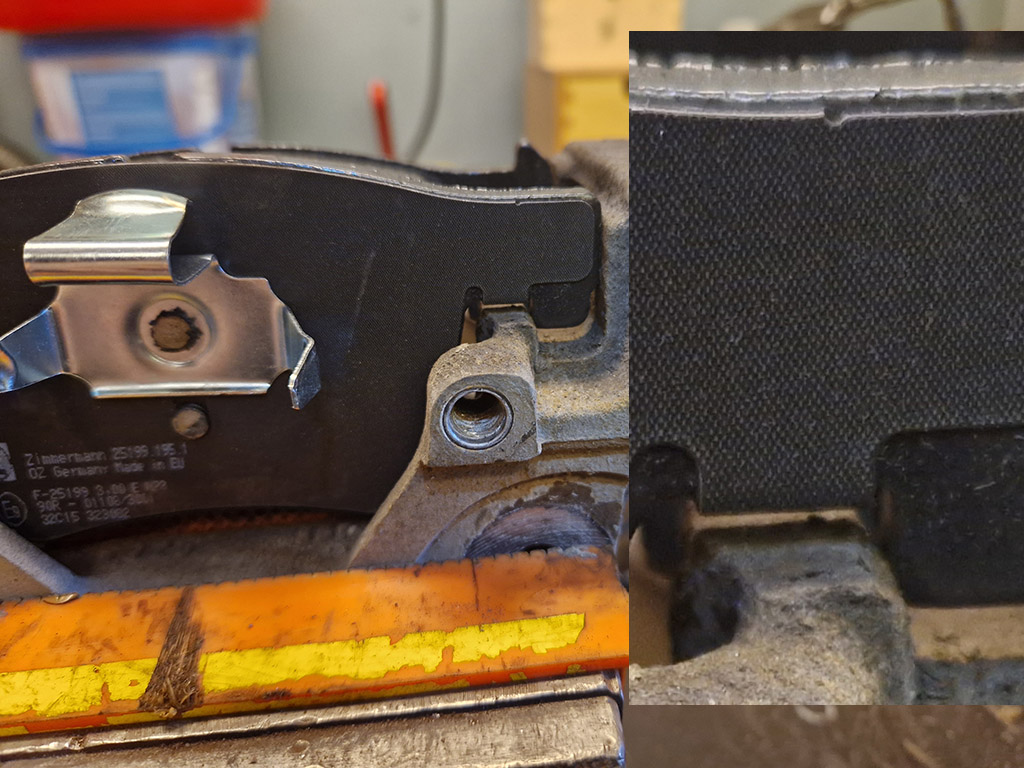

Brake pada and caliper braket

The new pads will need to be checked for fitment into caliper bracket

with the mounting clips in place etc.

If the pads can not move freely you should not cut or modify the pad

since this will make it easier for rust to damage them.

As can be seen in picture below, the pad is unable to rest on

glide surface.

By using dremel, chisel or metal file, clean the surface of the caliper bracket so that the pad can slide easily.

Do not add grease or copper paste, it will only grime up and collect dirt.

In the clip below, movement that is correct can be seen.

New wear indicator

Pushed in place, try avoiding bending or braking the wires.

Reinstallation

assembly is in reverse order.

After filling the brake reservoir, bleeding the brakes

is done to ensure no airbubbles are present.

All parts in place, new retainer clip

Old brake parts to bin

Not too badly worn. not worth a "pad slap".

.

Service reset

1. Without touching brake or clutch, press start/stop to turn on the vehicle's electrical systems.

2.

Push down the small odometer button near the bottom-left corner of the spedometer for 10 seconds then release the button.

3. Click as many times as needed to reach desired reset option.

4. Press and hold again until the message says “Perform reset?”

5. hold down to accept and release when it is finsished.

Brake bed-in

This task is next on the list, the Zn coating on my new rotors need to be worn down so that the metal surface is exposed.

I did this with slow long brake ins, for a few km.

Wear surface after some 4000km

No stuttering nor shaking can be felt, there is no uneaven braking-