VW Sharan 2015

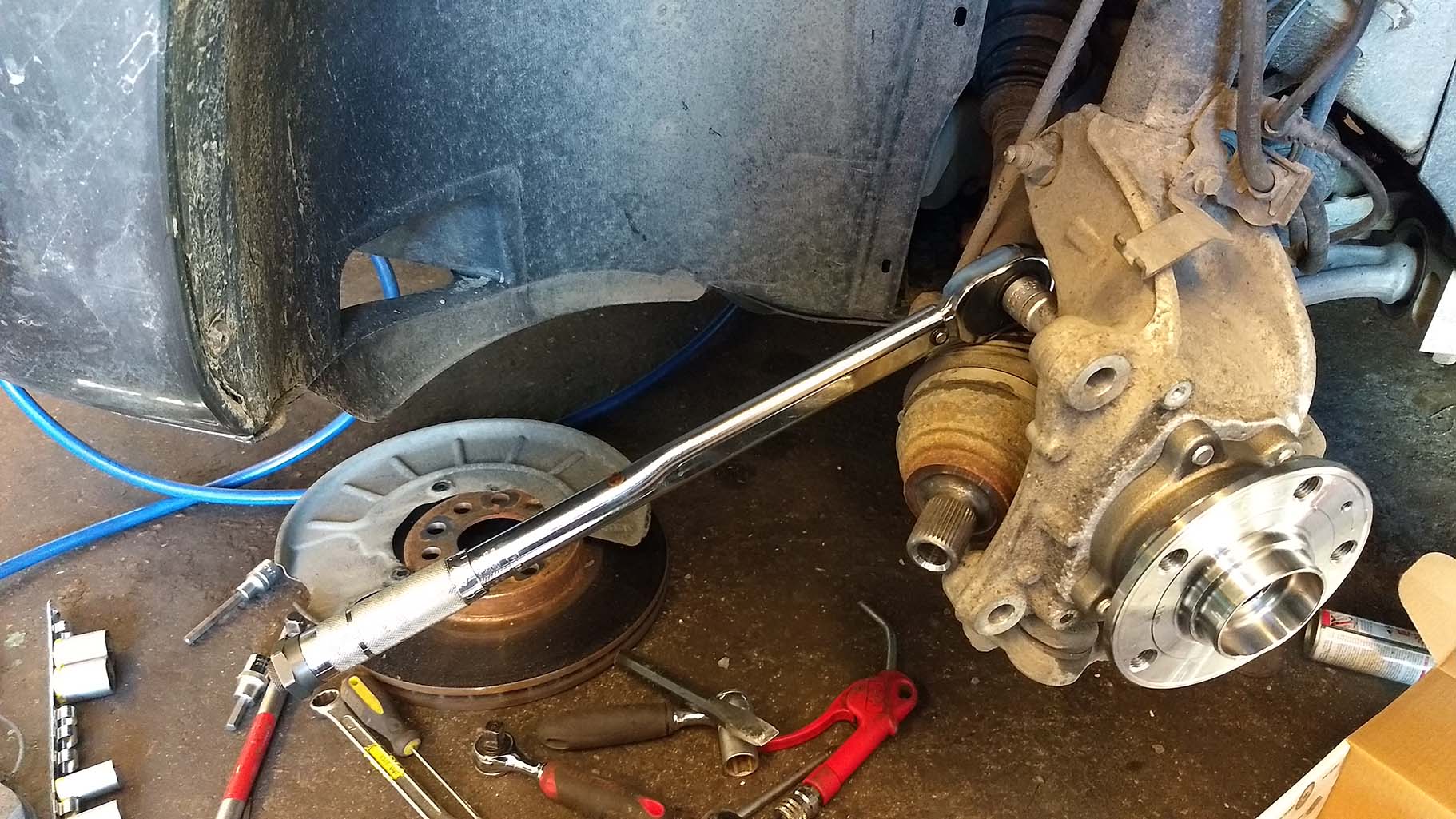

front wheel bearing replaced

The front end was increasingly noisy and a lot of rumbling

could be heard.

following is a teardown and procedure

special tools is not necessesary, but here are some recommendations

Tools

-No lubrication or anti seize agent should be used on new M12 or drive shaft bolt!

Your choice if 1/2" or 3/4"

* Proper square handle -should withstand 1000Nm

* A torque wrench 70Nm - 200Nm (51,6 - 147,5 ft-lb)

* M12 long and short

* 12 point 24mm socket

* Jackstands

* WD-40 or eq.

* Hot air gun or inductive heater

*

Impact screwdriver

* Slide hammer

Teardown

Lift and place the car on jackstands before teardown.

Remove caliper and bracket

Do not let it hang by the hose!

Remove disc

If there is need of force or excessive hammering in order to get the

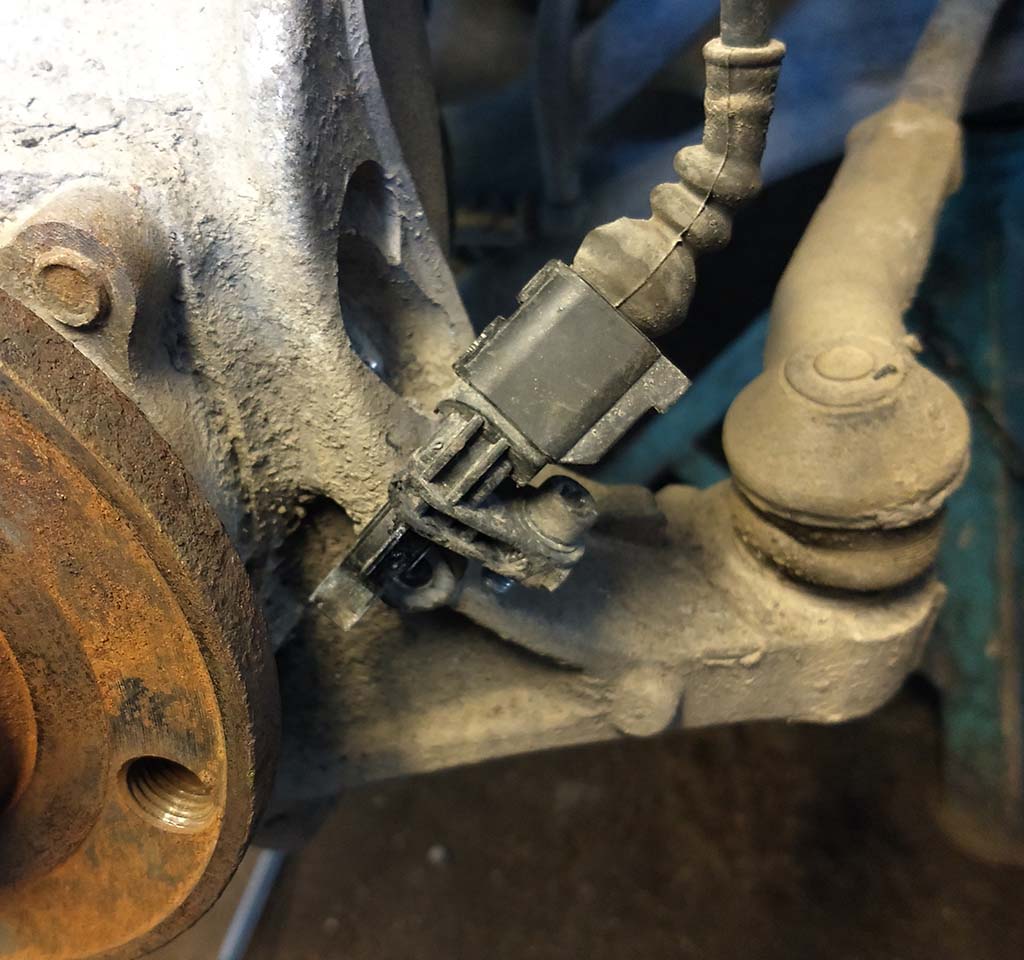

disc to come loose, suggest removing the ABS sensor. It could take damage from heat and impact.

It is not necessary to remove brake dust shield, but it helps a bit

remove the torx screws with impact screwdriver.

If rusted, remove with impact screwdriver

After removing bolt, drive shaft can be pushed in.

Guess it's time to replace it.

Removal of wheelbearing

Since this part requires heating and the use of hammers

ABS sensor was removed

Gently pry it out, do not pull by cord or

bend it.

Use wirebrush and clean the threads,

spray with penetrating oil. This is done before removing the M12 bolts.

There is a risk of stripping the head, resulting in more work than wanted.

Heat gun used to help the oil do its work.

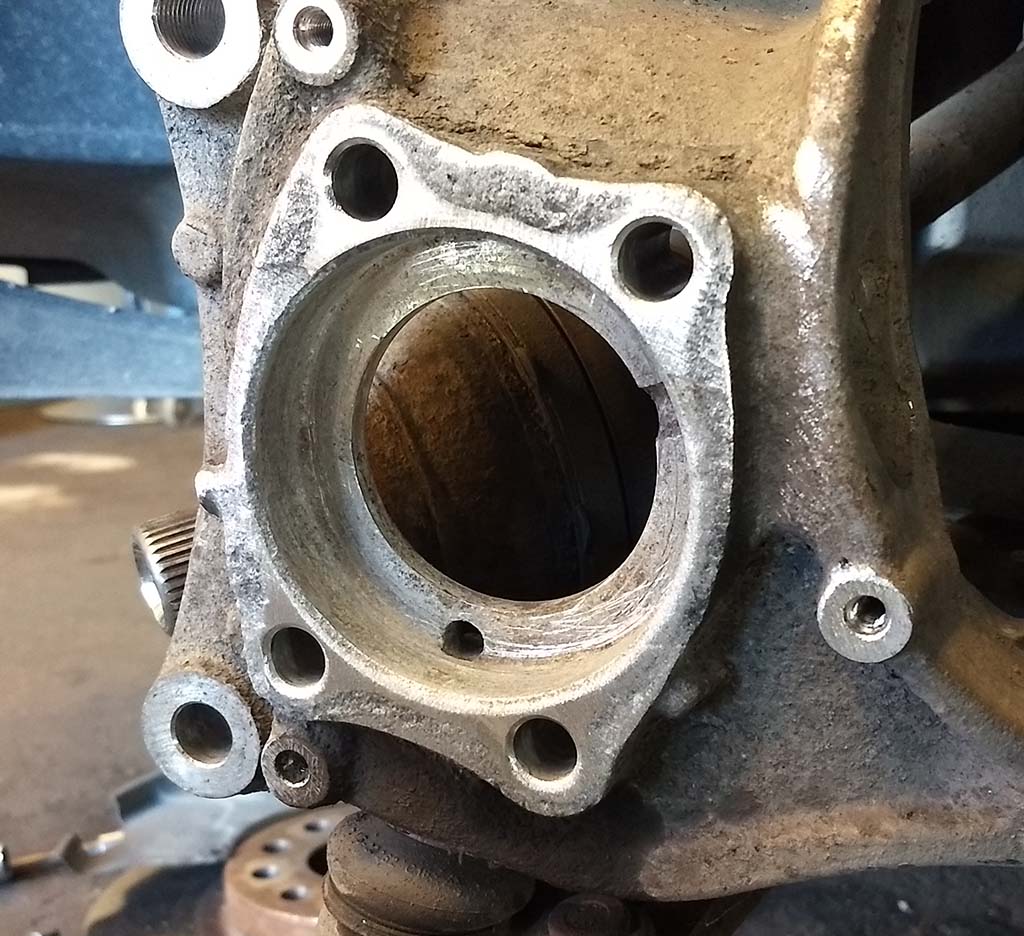

Use slide hammer to pull out the bearing housing, warming the spindle helps a bit.

Clean all areas thorougly before inserting the new housing.

Driveshaft and spindle does not have to be removed in order to replace the housing. just manouver the CV joint carefully without damaging the boot.

Make shure the M12 heads are clean before inserting bit.

Corrosion from salty road conditions painfully visible.

only 5 years and 240 000 km

or approx. 150 000 miles.

New bearing

M12 bolts initial torque 70Nm (51,6 ft-lb)

-No lubrication or anti seize agent should be used!

after initial torque turn an additional

90°, use a marking pen for start stop points, here is where the short M12 bit should be used.

Final

Insert the drive shaft and gently by hand thread the new bolt into place, do not torque yet!

Assembly in reverse order for all remaing components.

Step 1:

If you have assistance, have the person sit in car and apply the brakes but make sure you have at least two wheelbolts threaded before you start torquing the drive shaft bolt.

Initial torque 200Nm (147,5 ft-lb)

-No lubrication or anti seize agent should be used!

Step 2:

Either put the wheel back and seat the car, pull handbrake and have your helper apply brakes or continue with the car still on jackstands

but insert all the wheelbolts.

Mark with pen and torque an additional 180° for the bolt, be careful not to injure yourself in case your square handle brakes.