Z5500 amplifier swap

The problem

A friend lost functionality of the head unit for the Z-5500 setup

Simplest plan was transplanting the amp for a subwoofer kit and then connect the satellites to a home theater receiver, thus a 5.1 system is complete.

There is no point attempting to repair the board since I do

not have acces to schematics, the PCB might not be the only broken part.

Teardown

There's no fancy procedure to dissasembly, just remove all the screws and tear out the guts.

The power and fuse connectors

are glued, not bothering with them.

Not using old weak transformer...

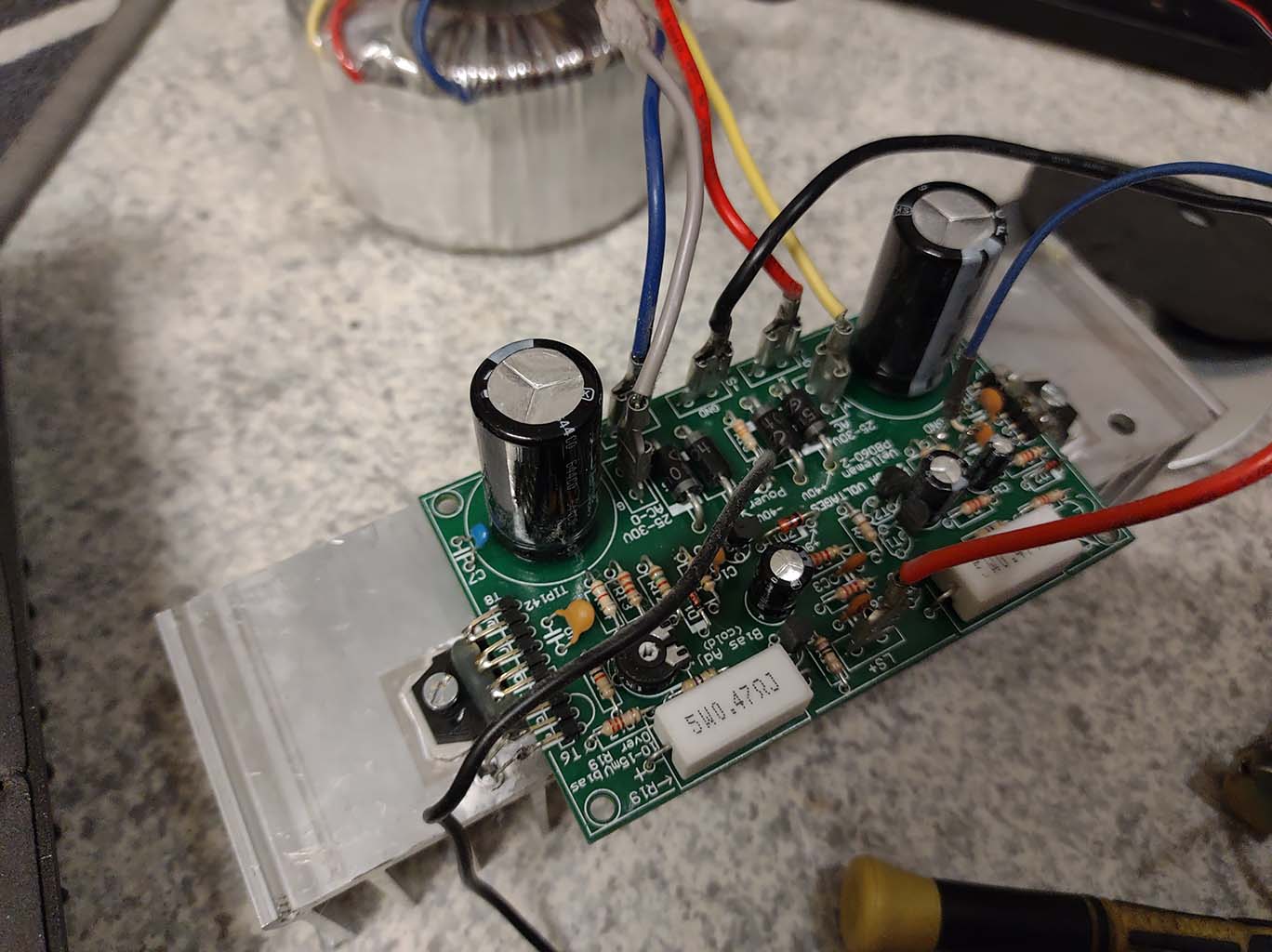

Adding a new amplifier

Had an old amplifier board from an earlier subwoofer build.

This PCB kit is Velleman 100W

RMS model WMAH100

WMAH100, class D - needs new caps.

the previous build was never turned off for some 10+ years

old, swollen.

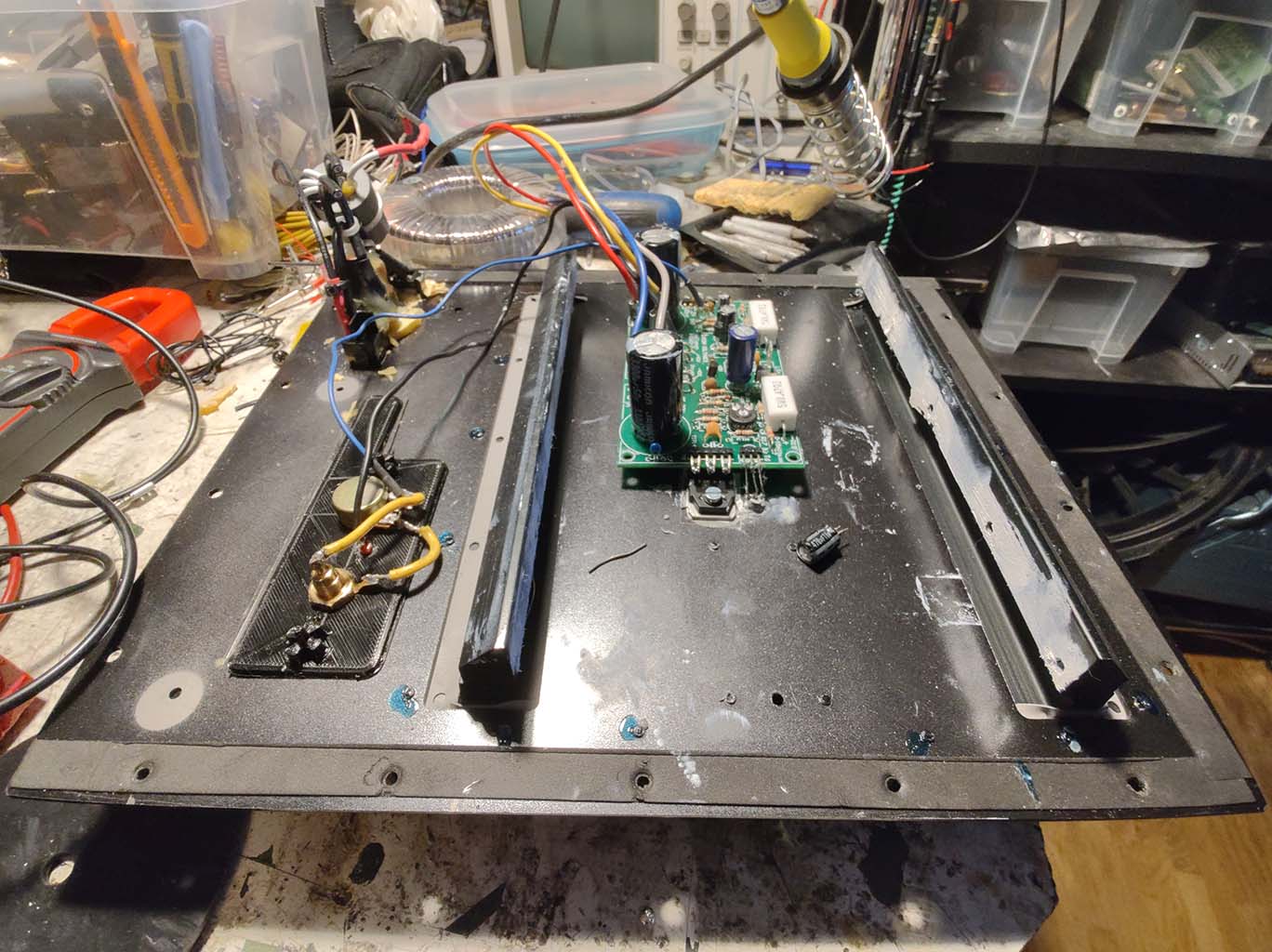

Amplifier installation

Drilled holes and mounted transistor.

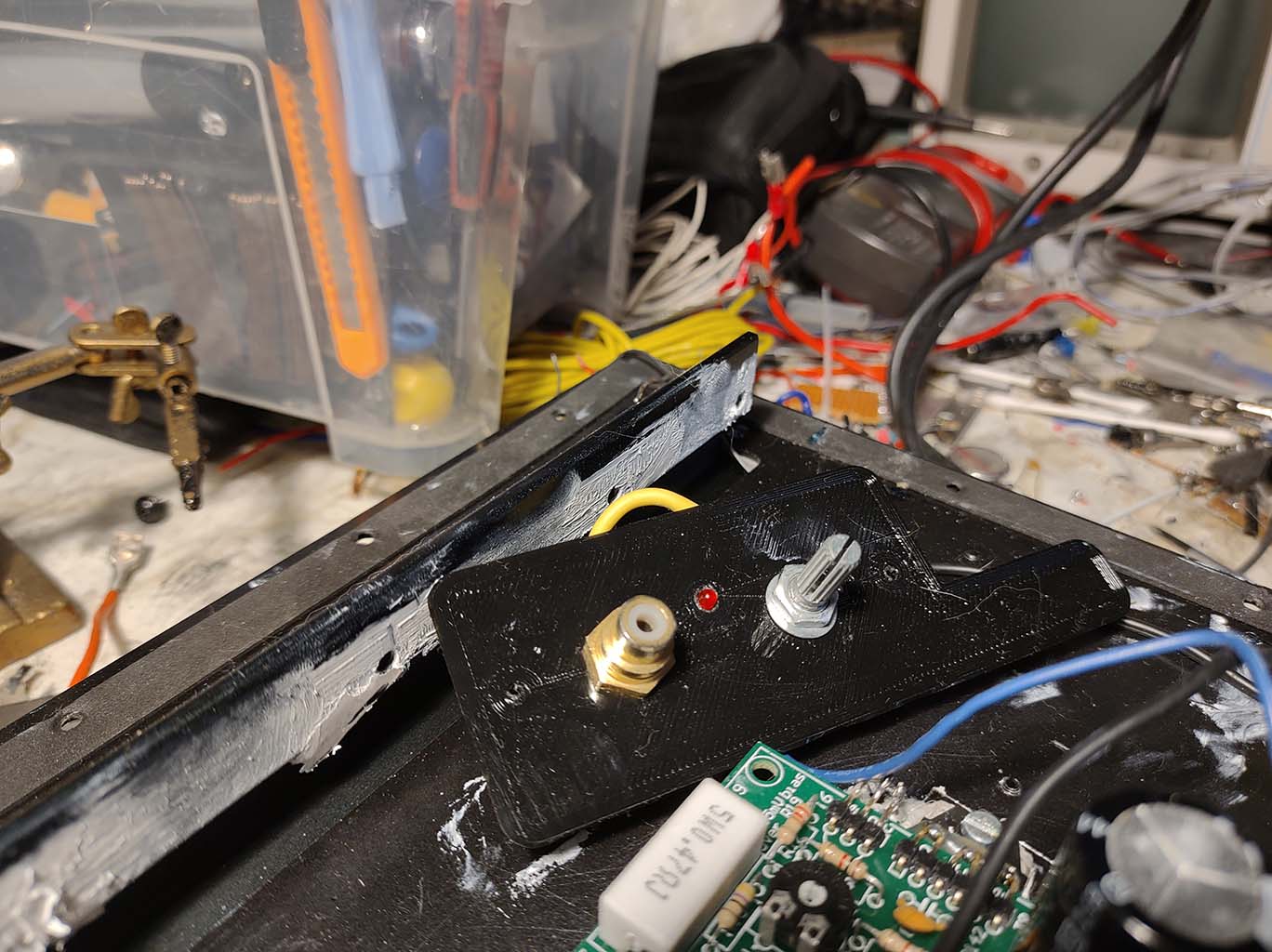

Poentiometer and RCA

Speaker connection hole can be repurposed

to hold interface and status LED

Done adding all parts,

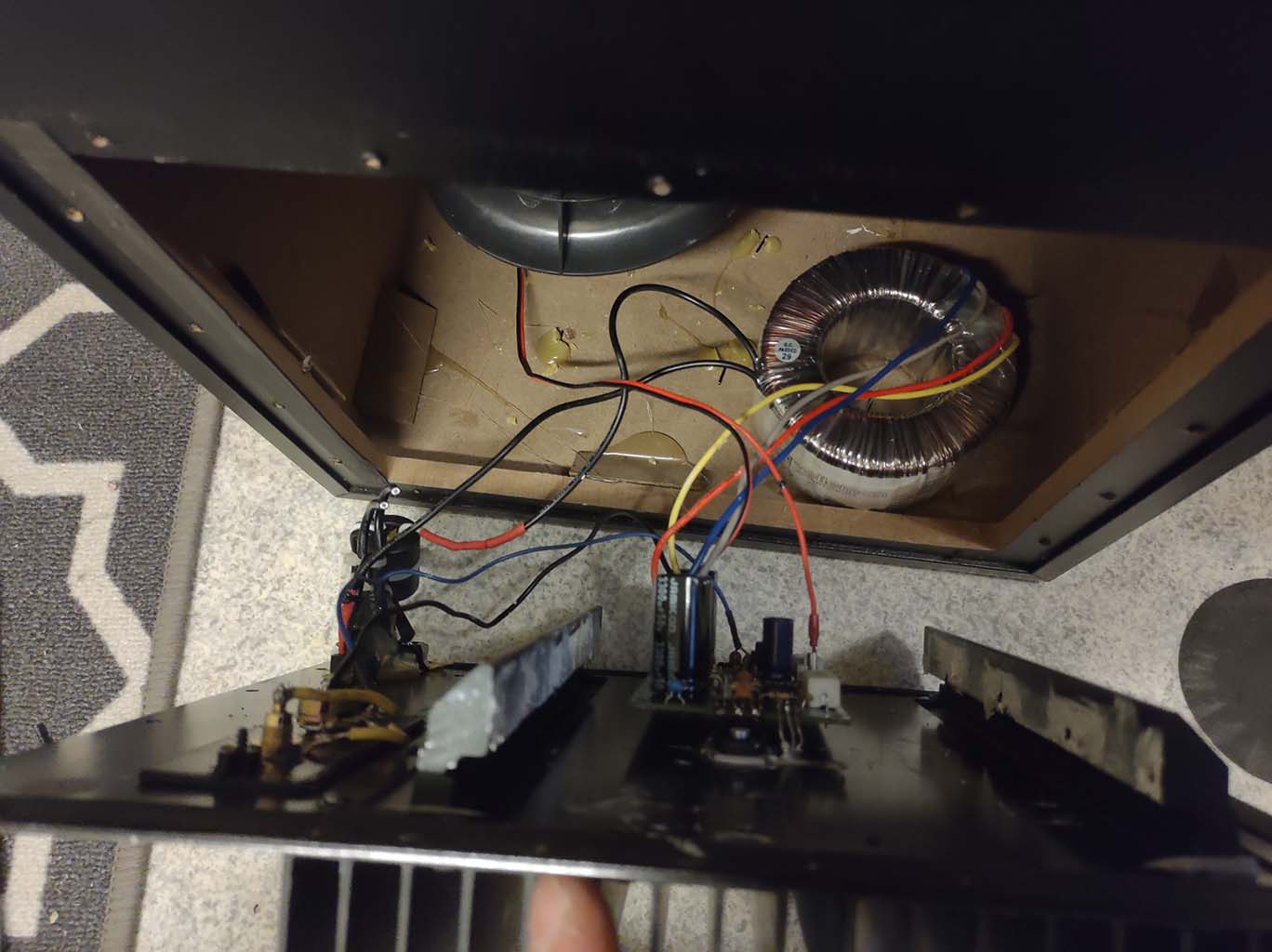

Power source

I'll be using a 120VA 2 x 30V / 2 x 2.00A

toroid transformer.

It will be suitable and can handle 60W RMS.

Amplifier board is 100W RMS, and the subwoofer

is most likely just about good for 150W max.

120VA 2x30V/2x2.00A Toroid Transformer

10mm hole drilled and a bolt with glue will hold it down

as mounting

All installed

Trying to find picture / video

Final -210606

As of -241114 - Subwoofer is still in use, working fine

Please check out :

Speaker info

Seems like Logitech rebranded a Tang Band WT-644F

(random google sources)

Sensitivity (1W, 1m, infinite baffle)

SPL1W 91.3 dB

Frequency response 32 - 600 Hz

Thiele & Small parameters

Resonance frequency (free air) fS 32.0 Hz

Mechanical quality factor QMS 11.19

Electrical quality factor QES 0.43

Total quality factor QTS 0.42 ¨

Large signal parameters

Maximum linear excursion xmax 9.25 mm

Air volume displaced at xmax VD 324 cm³

Power handling P 180 W

Program power Pmax 360 W

Voice Coil Nominal impedance Z 2 x 8 Ω

DC resistance (in series) RE 12.8 Ω

Inductance (1kHz, in series) LE 6.68 mH

VC Diameter 50 mm Magnet Force factor (in series)

Bl 29.08 N/A Motor constant Bl/√RE 8.13 N/√W

Air gap height HAG 8 mm

Material Ferrite

Diaphragm Effective diameter 211 mm

Effective area SD 350 cm²

Moving mass MMS 69.9 g

Moving mass (without air load)

MMD 65.2 g

Material Paper Suspensions Stiffness KMS 2.92 N/mm

Compliance CMS 342 µm/N

Equivalent volume to the compliance

VAS 59.5 L Mechanical resistance RMS 1.26 N·s/m

Surround material Foam

Dimensions Nominal diameter 10 ″ 254 mm

Volume occupied by the driver (estimated) 1.9 L

Net weight 4.5 kg

.png)